Technical Apparel Production E-Folio Journal

Capstone Project: High-Performance Field Pants for Archaeologists

Portfolio Projects

Collection of completed projects demonstrating technical skills and design proficiency developed throughout the program.

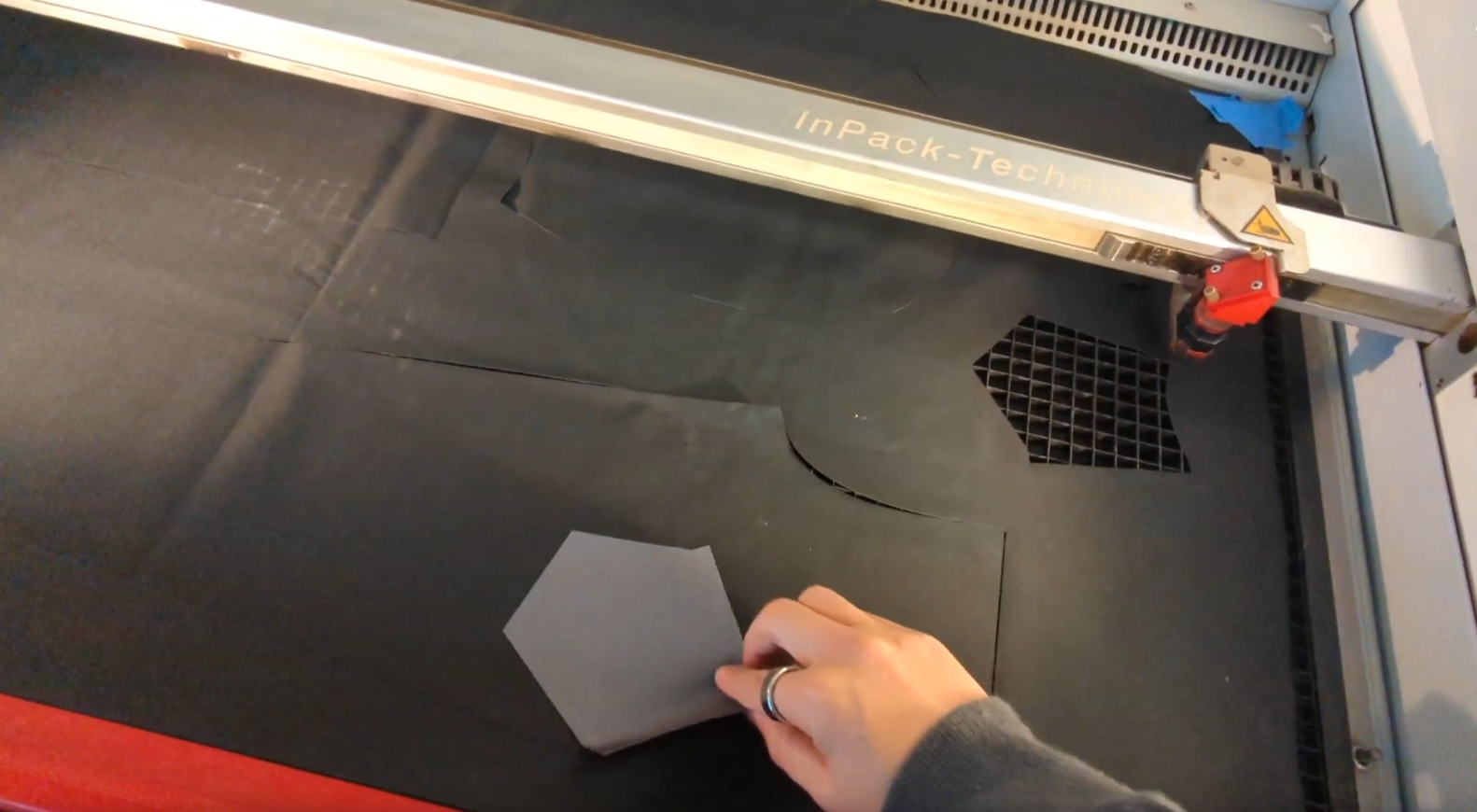

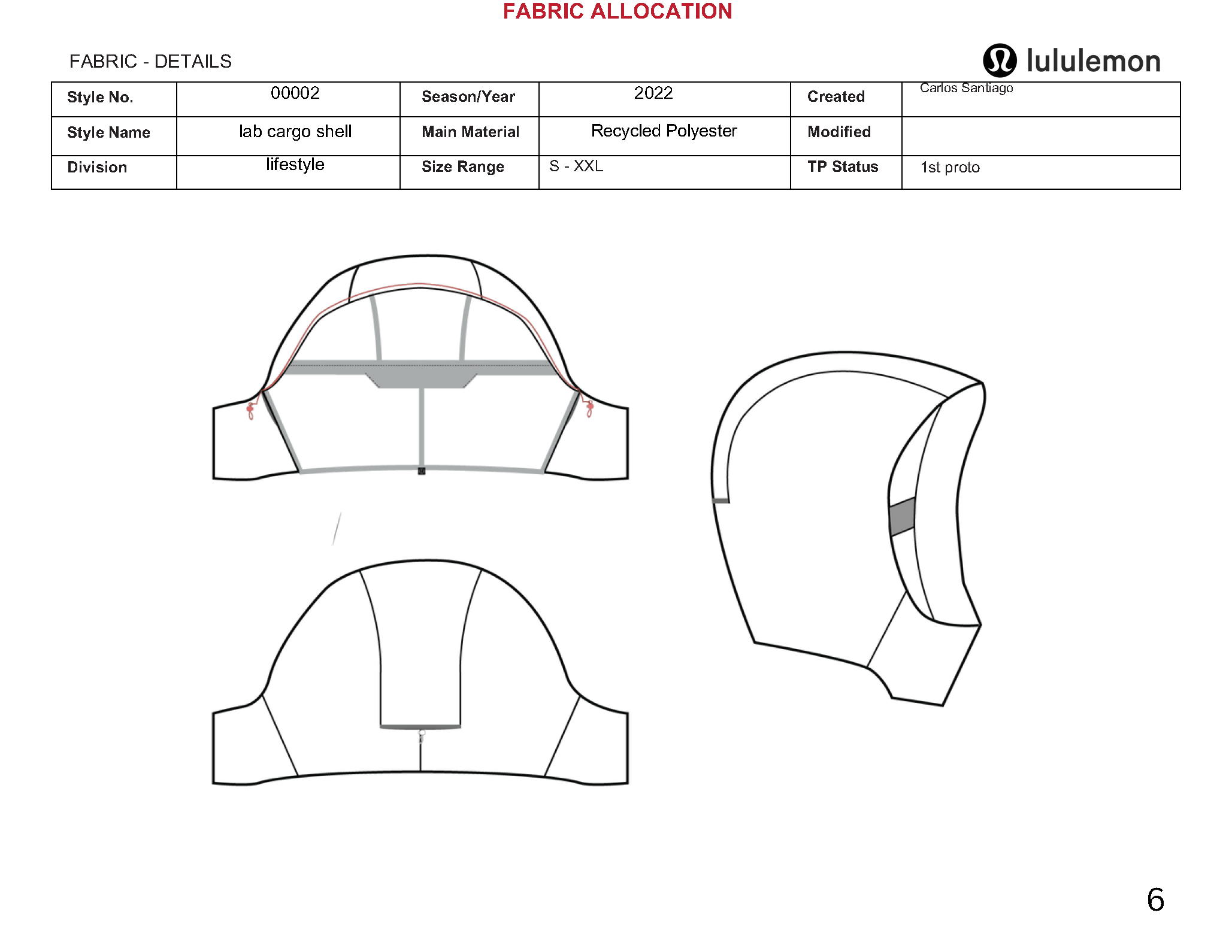

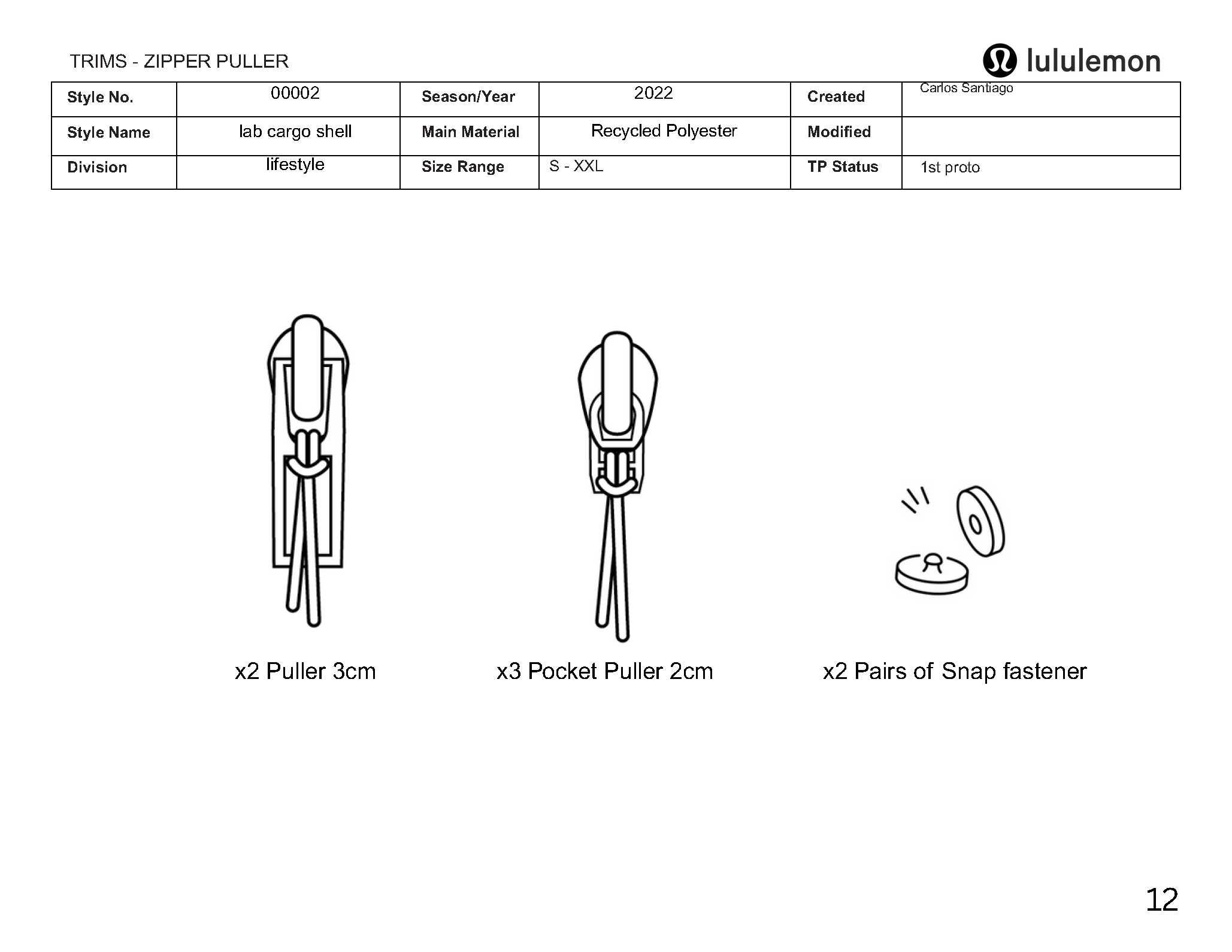

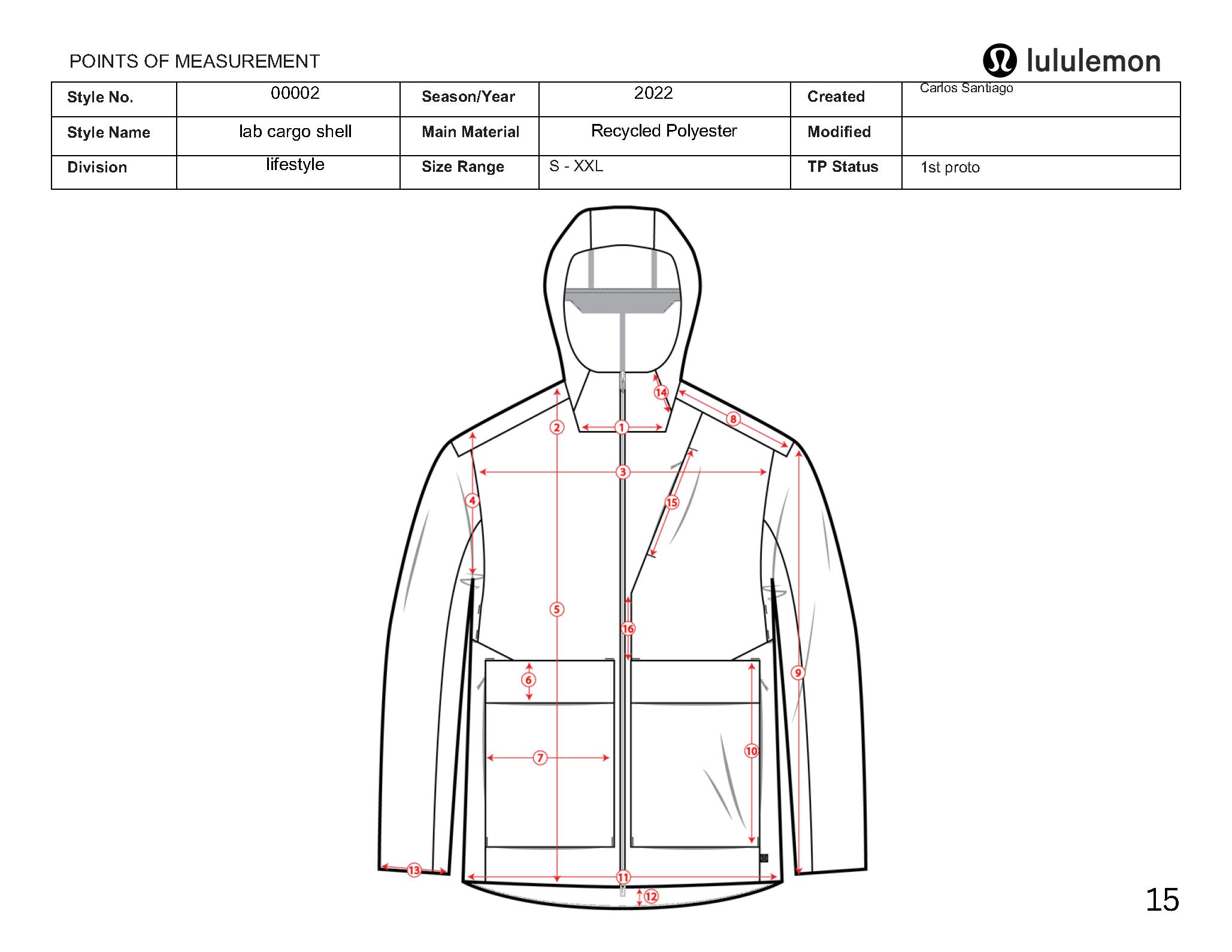

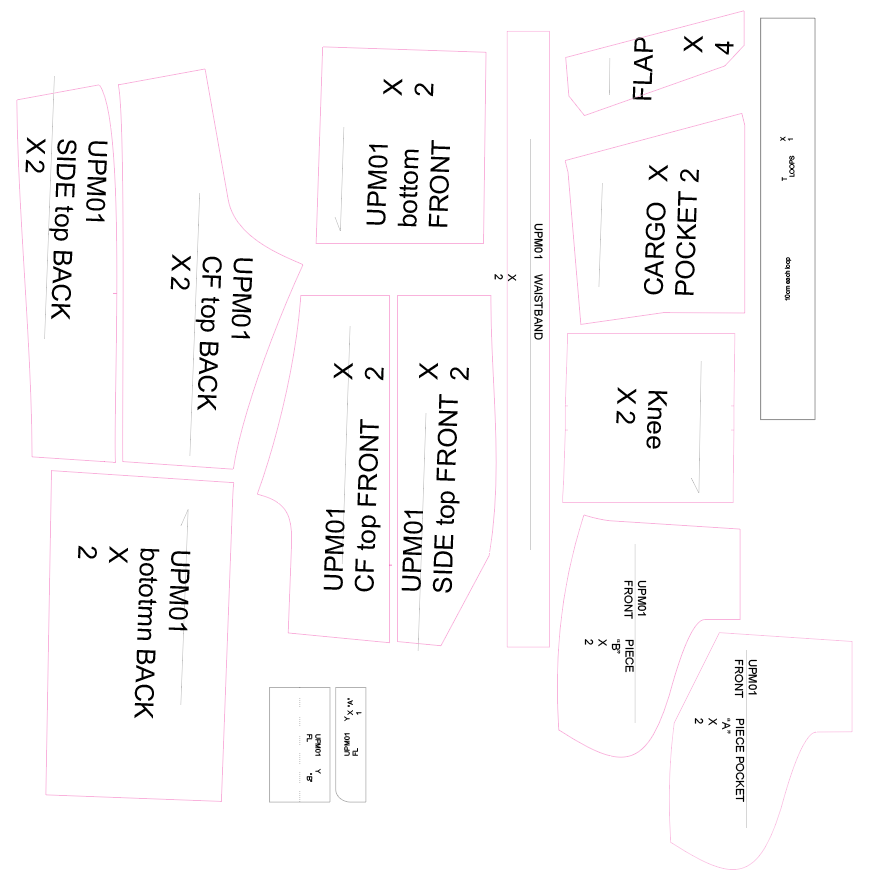

Created a waterproof jacket inspired by the Lululemon Cargo Shell Jacket. Utilized Adobe Illustrator for pattern tracing, Browzwear VStitcher for 3D fit assessment, and laser cutting for precision fabrication.

Implemented no-seam pocket technology, seamless zipper attachment, and waterproof tape sealing on all interior seams. Successfully passed wear testing for water repellency.

Skills Developed: Browzwear VStitcher proficiency, laser cutting techniques, seam sealing methods, and understanding of construction challenges in technical apparel.

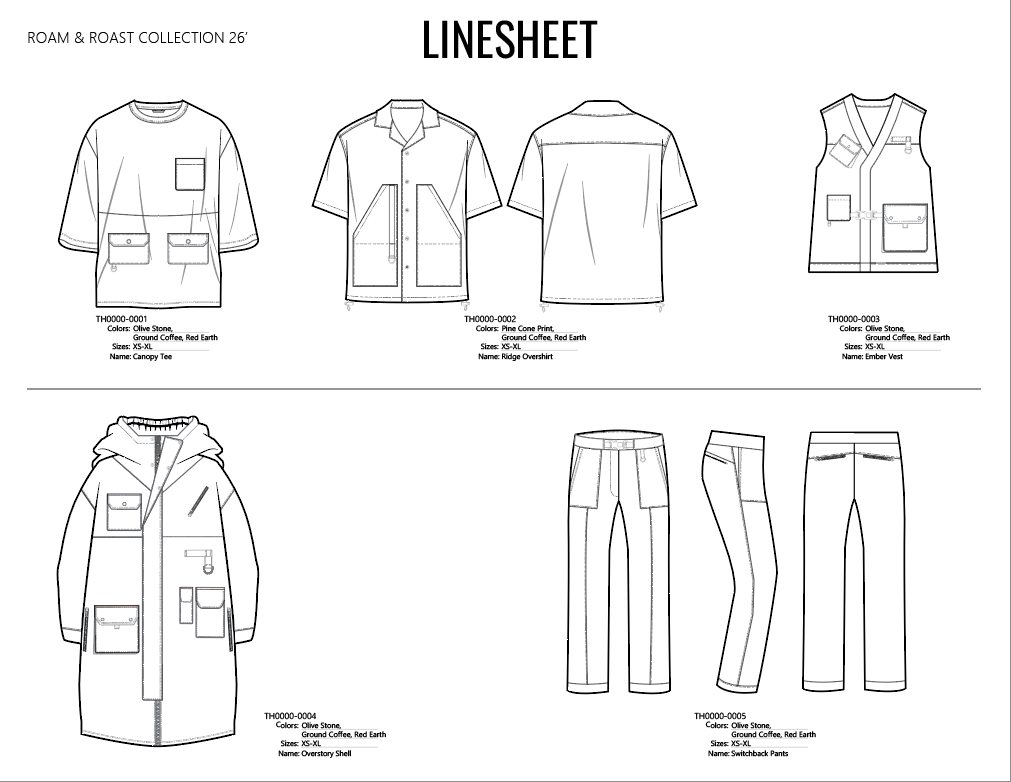

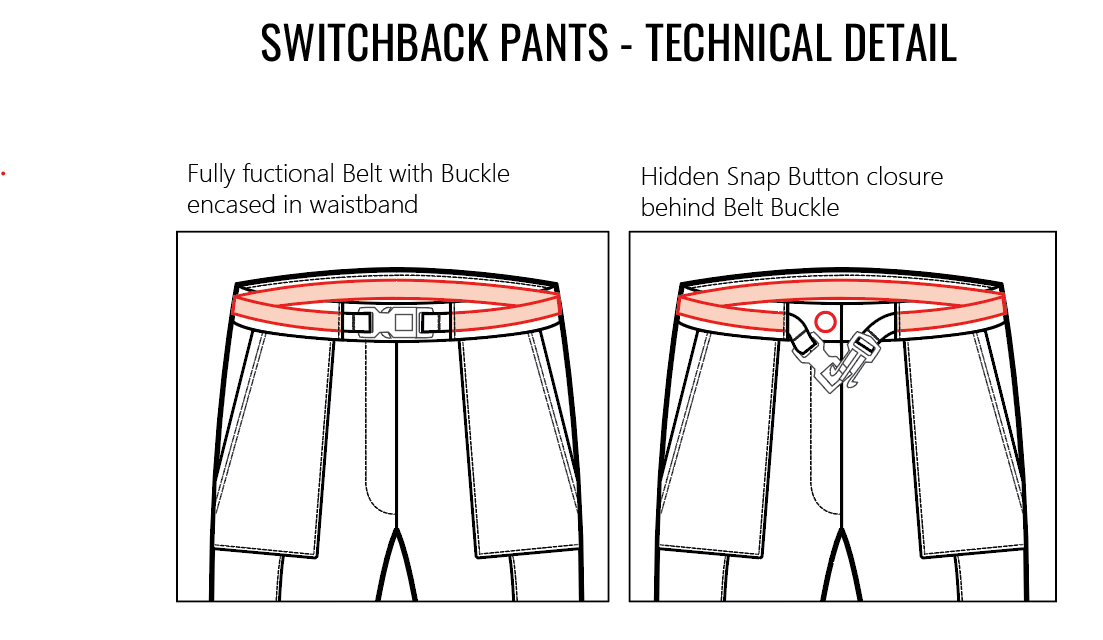

Developed a comprehensive line sheet showcasing Adobe Illustrator skills for creating precise technical drawings of a cohesive hiking apparel collection.

Skills Demonstrated: Technical illustration, construction detail communication, functional design for performance apparel.

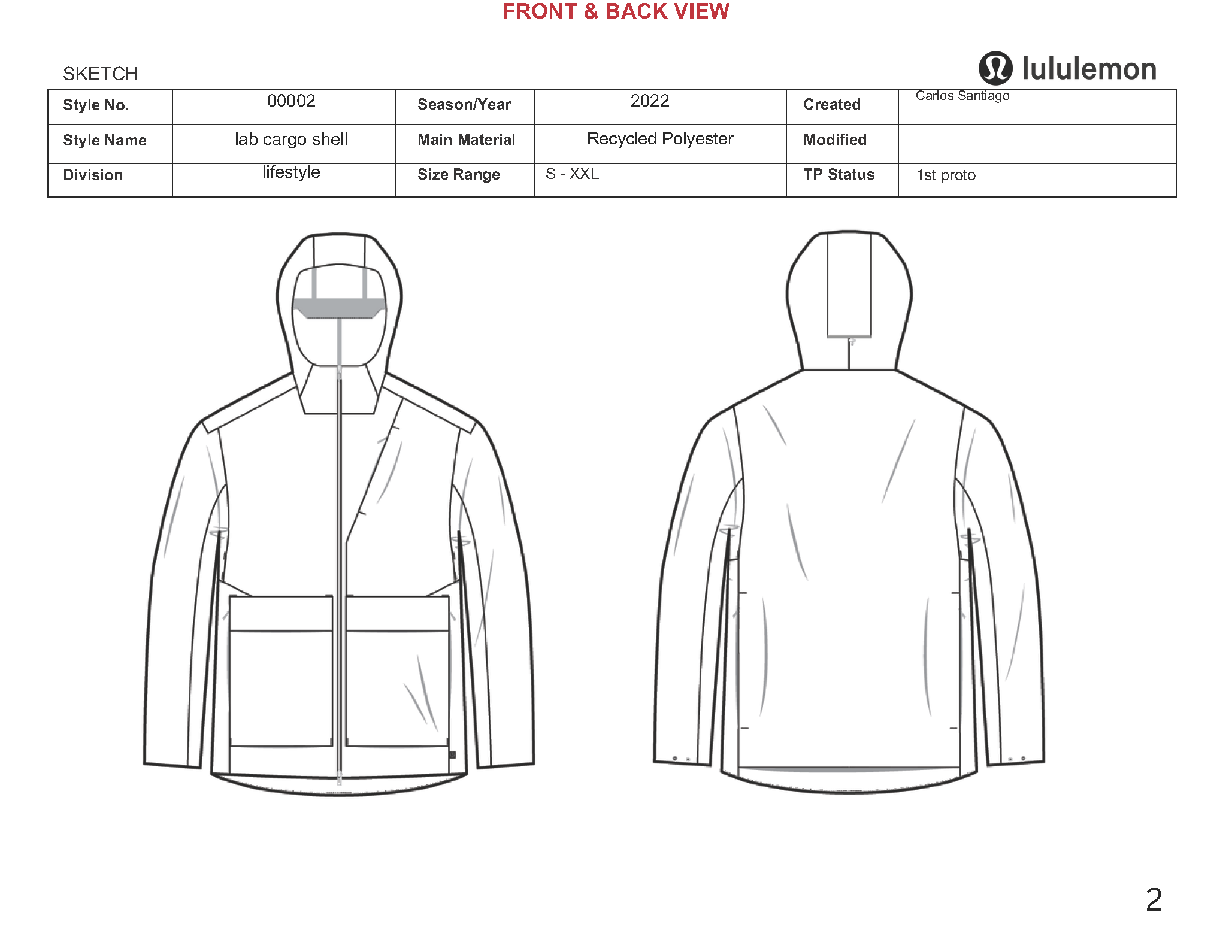

Reverse-engineered the Lululemon Cargo Shell jacket to create a complete tech pack including detailed technical drawings, construction callouts, and specification sheets.

Skills Demonstrated: Garment analysis, technical illustration, precision documentation for production communication.

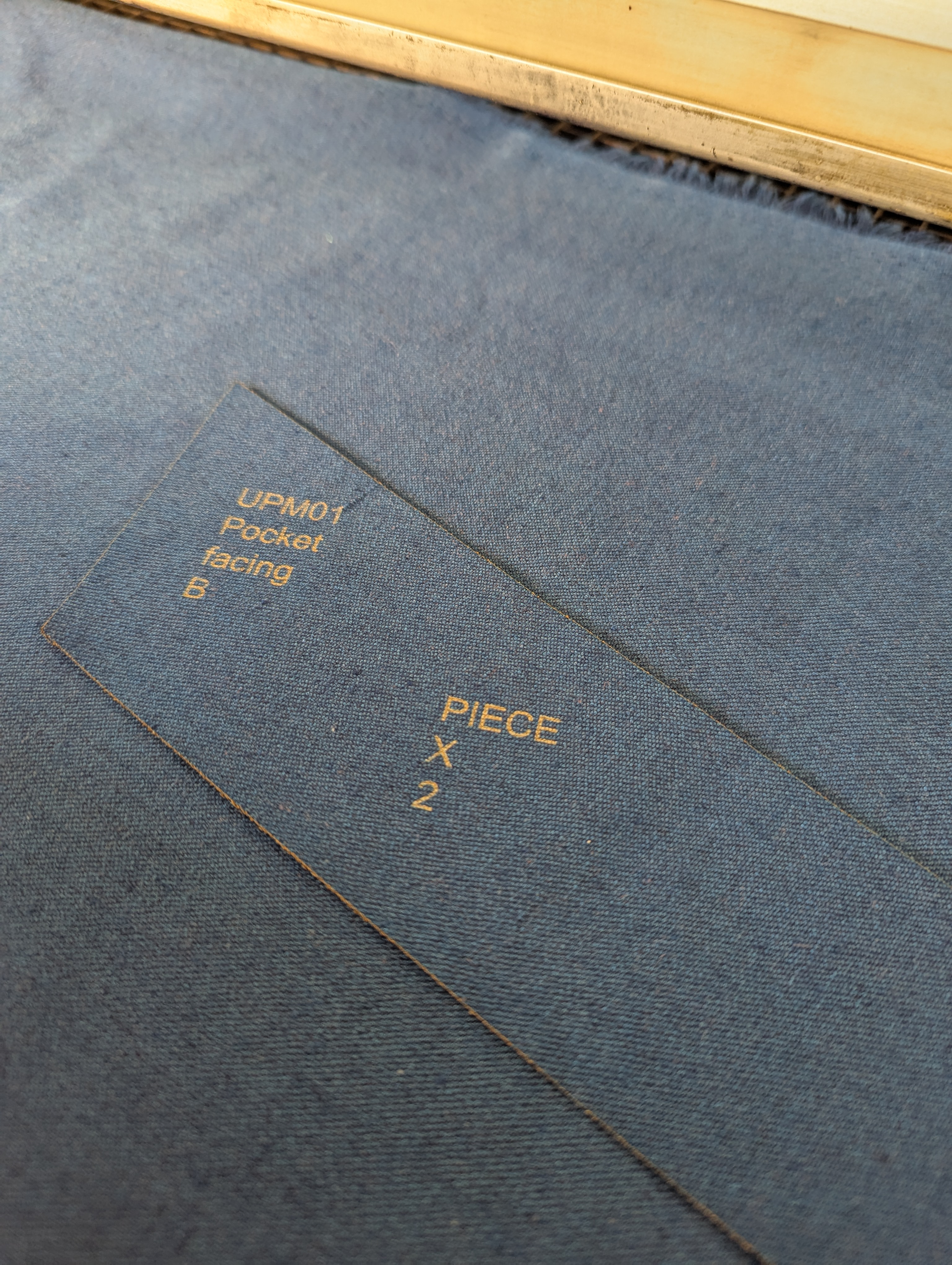

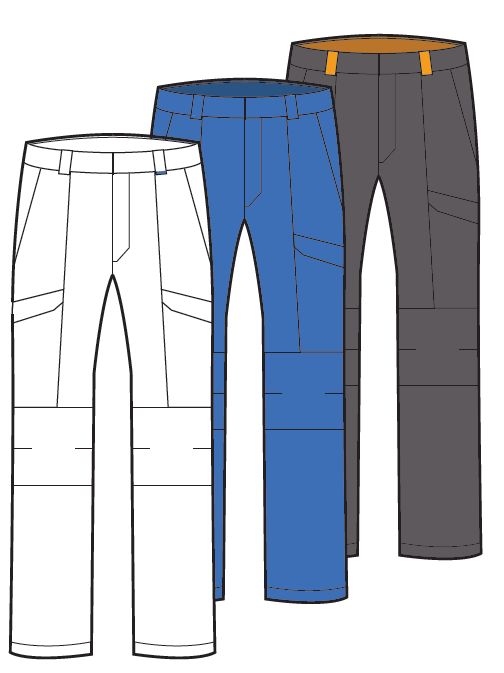

Developed firefighter pants inspired by Arc'teryx's performance aesthetic. Created technical drawings, designed and laser-cut pattern pieces, constructed the garment, and applied laser engraving for branding details.

Responsible for pant development within a full collection group project.

Skills Demonstrated: Technical design, pattern development, garment construction, laser cutting/engraving, branding design.

Independent Research

In-depth research supporting the technical production process, covering manufacturing methodologies, sustainability considerations, and fit development protocols.

Production Methodologies

Gore-Tex Pro Construction

- →PTFE vs ePE membrane comparison

- →3-layer laminate bonding process

- →Microporous membrane technology

- →Seam sealing with polyurethane tape

- →Heat-activated adhesive application

Articulation Pattern Design

- →Movement accommodation through pattern modification

- →Ergonomic considerations for fieldwork

- →Integration of stretch panels at strategic points

- →Action pleat placement and sizing

- →Anatomical mapping for natural movement

Waterproof Pocket Engineering

- →Zippered pocket construction techniques

- →Water-tight construction methods

- →Gasket integration for seal integrity

- →Interior pocket bag lamination

- →Drainage considerations

Sustainability Research

Environmental Impact Analysis

- →PFAS environmental concerns and bioaccumulation

- →Water contamination from PTFE production

- →Long-term environmental persistence

- →Regulatory landscape and restrictions

- →Industry transition timelines

Sustainable Material Alternatives

- →ePE PFAS-free alternative benefits

- →Reduced carbon footprint of ePE membrane

- →Recycled textile integration opportunities

- →Bio-based membrane research

- →Performance comparison: traditional vs sustainable

Production Best Practices

- →Water conservation in manufacturing

- →Energy efficiency in lamination

- →Waste reduction strategies

- →End-of-life recyclability

- →Supply chain transparency

Peer-Reviewed Literature & Technical Research

Design decisions are grounded in peer-reviewed research spanning ergonomic apparel design, advanced textile technologies, and occupational health studies.

Key Finding: Specialized apparel reduces injury risk in physically demanding occupations through ergonomic pattern design and strategic reinforcement placement.

Relevance to Capstone: Military personnel and field archaeologists share similar physical demands—both require constant crouching, kneeling, and repetitive movements. This research validates the articulated knee design and high-waist construction approach.

Articulated knee construction with 15-20° forward angle and strategic reinforcement at high-stress zones directly applies military ergonomic principles to archaeological fieldwork.

Key Finding: Balance between protection and breathability is critical for outdoor worker performance. Waterproof garments that trap heat lead to reduced work capacity.

Relevance to Capstone: With 93% of survey respondents working 7+ hours outdoors daily and 86% reporting frequent weather impact, breathability is essential. This justifies Gore-Tex Pro 3-layer selection (RET <6).

Gore-Tex Pro N40r-X (RET <6) for torso/arms provides optimal moisture-vapor transmission. Schoeller c_change 4-way stretch enhances breathability during excavation.

Key Finding: Nanocomposite coatings increase abrasion resistance by 30-50% compared to traditional textile treatments, extending garment lifespan.

Relevance to Capstone: Survey respondents identified durability as the highest-priority attribute (4.71/5.0) with the largest satisfaction gap (-1.64). This validates material selection combining traditional waxed cotton with advanced membranes.

Double-layer Halley Stevensons 8oz waxed cotton at knees/seat provides traditional abrasion resistance. Gore-Tex Pro N80p-X combines modern membrane technology with 100,000+ Martindale cycles durability.

Key Finding: Hydrophilic polyurethane membranes offer waterproof-breathable performance without PFAS chemistry, addressing environmental concerns while maintaining technical standards.

Relevance to Capstone: Validates feasibility of transitioning from ePTFE (PFAS-containing) to ePE (PFAS-free) membranes for future production, supporting sustainability goals.

Gore-Tex ePE membrane (PFAS-free, 30% lower carbon footprint) represents the planned material transition path, maintaining 28,000mm waterproof rating and RET <6 breathability.

Key Finding: Anthropometric integration with movement analysis enables task-specific apparel design. Garments designed for specific occupational movements significantly outperform generic alternatives.

Relevance to Capstone: Validates the research methodology—conducting user surveys to identify specific movement patterns (93% constant/frequent crouching), then designing articulation accordingly.

Survey data on physical demands directly informs pattern articulation angles (15-20° knee), waist rise specifications (26.5cm front, 32-34cm back), and pocket placement optimization.

User Research Findings (n=14)

Key Research Insight

93% of CRM archaeologists crouch/kneel constantly or frequently during fieldwork

yet existing field apparel shows significant satisfaction gaps in mobility (-1.50), durability (-1.64), and tool access (-1.64). This quantitative evidence directly informs the articulated knee design, reinforced high-wear zones, and optimized pocket system in the capstone project.

Survey Demographics

Survey conducted with 14 CRM (Cultural Resource Management) archaeologists working in active field conditions. Respondents represent diverse experience levels (1-20 years) and roles including field technicians, crew chiefs, and project managers. Average experience: 6.9 years.

Figure 1: User Research Survey Demographics showing experience distribution and physical demands

Physical Demands

- →93% crouch/kneel constantly or frequently (13/14 respondents)

- →50% crouch constantly, 43% frequently

- →93% work 7+ hours outdoors daily (avg 7-9 hours, up to 10+)

- →86% report weather impact often or almost always

Design Implication: Articulated knee construction with 15-20° forward angle and reinforced high-wear zones are critical requirements.

Satisfaction Gap Analysis

- →Durability: -1.64 gap (Importance 4.71, Satisfaction 3.07)

- →Tool Access: -1.64 gap (Importance 4.57, Satisfaction 2.93)

- →Mobility: -1.50 gap (Importance 4.14, Satisfaction 2.64)

- →Breathability: -1.36 gap (Importance 4.50, Satisfaction 3.14)

Design Implication: These gaps represent the highest-priority design requirements.

Top Challenges Reported

- →57% Restricted Movement (8/14) - #1 challenge

- →50% Durability Issues (7/14) - Fabric wears out quickly

- →50% Poor Pocket Design (7/14) - Inadequate tool access

- →43% Rain/Wetness issues (6/14)

- →36% Poor Ventilation (5/14)

Design Implication: 4-way stretch, double-layer reinforcement, optimized pockets.

Figure 2 & 3: Satisfaction gaps and primary field apparel challenges identified through user research

User-Stated Ideal Features

Movement & Fit

- →"Stretch fabric that moves with you during crouching"

- →"Articulated knees that don't bind"

- →"High waist that stays put when bending"

- →"Reinforced seat and knees that last seasons"

Weather Protection

- →"Waterproof but breathable—not a sauna"

- →"Keeps rain out without overheating"

- →"Quick-drying after creek crossings"

- →"Wind resistance for exposed ridge work"

Tool Access & Storage

- →"Pockets deep enough for field notebook and trowel"

- →"Easy access without taking off pack"

- →"Waterproof zippers for documentation"

- →"Tool loops that actually hold tools securely"

Market Opportunity Analysis

Market Size

15,000 professional field archaeologists

represent the total addressable market in North America, with 3,700 active field technicians as the primary target segment. CRM industry growth: $1.46B to $1.85B (2022-2031) represents 47% expansion over 10 years, creating favorable market conditions for specialized technical apparel.

Market Segmentation

- →Total Archaeologists: 16,000-21,500 in North America

- →CRM Percentage: 90% work in Cultural Resource Management

- →Active Field Technicians: 3,700 (Primary target)

- →Permanent Field Staff: 8,000-10,000 (Secondary target)

- →Total Addressable Market: 15,000 professionals

Industry Growth Drivers

- →47% industry expansion projected 2022-2031

- →Revenue growth from $1.46B to $1.85B

- →Infrastructure development increasing field projects

- →Environmental compliance requirements

- →Cultural heritage preservation mandates

Competitive Gap Analysis

- →Gap 1: No existing products combine advanced moisture-vapor transmission with archaeology-specific reinforcement

- →Gap 2: Generic outdoor pants lack ergonomic design for constant crouching/kneeling

- →Gap 3: Inadequate integrated tool-access storage systems

- →Gap 4: Poor antimicrobial/quick-dry for multi-day expeditions

- →Gap 5: Limited field repairability options

Commercial Viability Assessment

At a recommended retail price of $650 USD, the product targets professional archaeologists who prioritize performance and durability over cost. With production costs averaging $127/unit (material $57-76, labor $30-75), gross margins support specialty retail channels and direct-to-consumer sales.

The 15,000-person addressable market, combined with strong industry growth (47% over 10 years) and clear competitive gaps, demonstrates commercial opportunity. User research confirms willingness to invest in specialized technical apparel that addresses unmet needs in mobility, durability, and tool access.

Production Specifications & Manufacturing Analysis

Detailed production analysis quantifies manufacturing complexity, material requirements, and cost structures.

Pattern Complexity

- →Pattern Pieces: 35-40 individual pieces

- →Seam Length: 8-10 meters requiring sealing

- →Assembly Time: 2-3 hours skilled labor

- →Multiple fabric zones (5 different materials)

Cost Breakdown

- →Material Costs: $57-76/unit

- →Labor Costs: $30-75/unit

- →Total Production: $92-161/unit (avg $127)

- →Recommended Retail: $650 USD

Quality Control Points

- →Seam sealing integrity inspection (100% coverage)

- →Waterproof zipper function testing

- →Articulation angle verification (15-20° ±2°)

- →DWR treatment application verification

Pocket System Specifications

Hip Cargo Pockets

- →Depth: 18-20cm

- →Closure: YKK waterproof zipper

- →Primary tool access (trowels, brushes)

- →Target: 30% reduction in tool retrieval time

Chest Pockets

- →Depth: 15cm

- →Closure: Waterproof zipper with storm flap

- →Documentation tools (notebook, GPS)

- →Accessible without removing backpack

Back Security Pocket

- →Depth: 16cm

- →Closure: Magnetic snap + waterproof zipper

- →Secure storage (phone, wallet, permits)

- →Dual-closure system prevents loss

Fit Specifications Table

| Measurement | Specification | Tolerance | Design Rationale |

|---|---|---|---|

| High Waist Rise (Front) | 26.5 cm | ±0.5 cm | Prevents gap during forward bending |

| High Waist Rise (Back) | 32-34 cm | ±0.5 cm | Extended coverage above natural waist |

| Knee Articulation Angle | 15-20° forward | ±2° | Optimized through testing for work simulation |

Material Selection & Zone Mapping

Multi-zone construction combines specialized fabrics optimized for specific performance requirements. Each material zone addresses distinct user needs identified through research.

Zone 1: Torso & Arms

- Material: Gore-Tex Pro N40r-X

- Weight: 109 g/m²

- Waterproof: 28,000mm

- Breathability: RET <6

- Rationale: Lightweight, maximum breathability

Zone 2: Shoulders & Back

- Material: Gore-Tex Pro N80p-X

- Weight: 150 g/m²

- Abrasion: 100,000+ Martindale cycles

- Rationale: Enhanced durability for backpack zones

Zone 3: Knees & Seat

- Material: Halley Stevensons 8oz Waxed Cotton

- Weight: 271 g/m²

- Construction: Double-layer reinforcement

- Rationale: Maximum protection for constant-contact zones

Zone 4: Elbows

- Material: Halley Stevensons 6oz Waxed Cotton

- Weight: 203 g/m²

- Construction: Single-layer reinforcement

- Rationale: Balances protection with mobility

Zone 5: Articulation Panels

- Material: Schoeller c_change 4-way stretch

- Weight: 205 g/m²

- Stretch: 4-way mechanical stretch

- Rationale: Maximum mobility at knees, crotch gusset, lower back

Material Selection Rationale

The multi-zone approach addresses the satisfaction gap between importance and current performance across key attributes:

- →Durability (-1.64 gap): Double-layer waxed cotton at knees/seat + Gore-Tex Pro 100,000+ Martindale cycles

- →Mobility (-1.50 gap): Schoeller 4-way stretch in articulation zones + ergonomic pattern design

- →Breathability (-1.36 gap): Gore-Tex Pro RET <6 + strategic ventilation panels

- →Waterproofing (importance 4.29): 28,000mm hydrostatic head + fully sealed seams

Gore-Tex Pro: ePTFE vs ePE Membrane Comparison

Gore-Tex Pro is available in two membrane technologies: traditional ePTFE (expanded PTFE, contains PFAS) and newer ePE (expanded Polyethylene, PFAS-free). Performance equivalence enables environmentally responsible material selection.

| Performance Metric | ePTFE (PFAS) | ePE (PFAS-Free) |

|---|---|---|

| Membrane Technology | Expanded PTFE | Expanded Polyethylene |

| Waterproof Rating | 28,000mm hydrostatic head | 28,000mm hydrostatic head |

| Breathability | RET <6 (excellent) | RET <6 (excellent) |

| Abrasion Resistance | 100,000+ Martindale cycles | 100,000+ Martindale cycles |

| PFAS Status | Contains PFAS | PFAS-Free |

| Carbon Footprint | Higher (baseline) | 30% lower than ePTFE |

| Commercial Availability | Industry standard (phasing out) | Commercial since 2022-2024 |

Performance Equivalence

- →Identical waterproof rating (28,000mm)

- →Identical breathability (RET <6)

- →Equivalent abrasion resistance (100,000+ cycles)

- →Same construction methods (3-layer laminate)

Environmental Benefits (ePE)

- →30% lower carbon footprint vs ePTFE

- →No PFAS bioaccumulation in environment

- →No long-term persistence concerns

- →Reduced water contamination risk

Regulatory Landscape

- →EU PFAS ban: Effective winter 2025/26

- →US state-level restrictions increasing

- →Industry voluntary phase-out commitments

- →Gore-Tex Pro ePE widely available

Recommendation: Transition to ePE

While the prototype may initially use ePTFE for cost/availability reasons, commercial production should transition to Gore-Tex Pro ePE for the following reasons:

- →Performance parity: No technical compromise—identical waterproof/breathable specs

- →Environmental responsibility: 30% carbon reduction + elimination of persistent chemicals

- →Regulatory compliance: Future-proof against PFAS restrictions

- →Market positioning: Aligns with professional archaeologists' environmental values

- →Long-term viability: ePTFE phase-out timeline accelerating industry-wide

Personal Reflections

Chronological journal entries documenting learning progression, challenges encountered, and insights gained throughout the technical apparel production course.

Understanding Waterproof Construction

Learning about seam sealing techniques revealed why every stitch creates a potential leak point. This understanding directly informed my approach to the capstone pants design, where I specified fully taped seams and waterproof zippers with gaskets.

Articulation Design Challenge

The challenge of designiing for movement while maintaining waterproof integrity led to innovative solutions. Articulated knees require careful pattern work to avoid excess fabric bunching while allowing full range of motion during fieldwork.

Material Selection and Sustainability

Researching Gore-Tex Pro vs ePE alternatives highlighted the industry tension between performance and environmental responsibility. While ePE offers PFAS-free benefits with lower carbon footprint, Gore-Tex Pro remains the performance standard. For commercial viability, transitioning to ePE would be ideal.

Fit Session Insights

Conducting fit sessions on the prototype revealed the importance of high-waist construction for fieldwork applications. The additional coverage prevents debris entry and provides core support during physically demanding activities.

Production Methodology Integration

Connecting technical production knowledge to business viability has been enlightening. Understanding manufacturing complexity, 58+ pieces and 5+ hours assembly time for technical outerweear, directly impacts pricing strategy and target market positioning.

Industry Insights & Future Direction

This course has transformed my understanding of technical apparel production from design concept to manufactured reality. The complexity of waterproof construction, the precision required in spec development, and the careful balance between performance and sustainability have all become clear. The technical apparel industry is at an inflection point performance standards remain high, but environmental consciousness is driving material innovation. My capstone project embodies this tension: specified with Gore-Tex Pro for proven performance, but researched with ePE alternatives in mind for future sustainability goals. The skills developed in pattern articulation, fit methodology, and construction sequencing will be foundational as I move into professional practice. The challenge ahead is maintaining technical excellence while pioneering more sustainable production methods.